In our latest Throwback Thursday, experienced cruisers work with a local resource who analyzes anchor performance to consider anchor options for their new boat.

This article originally appeared in the May 2022 issue of 48° North.

Choosing the right anchor is a decision that can perplex even the savviest boat owner. A good anchor offers immense peace of mind and can save our boats from ruin. We count on this essential piece of equipment to ensure that our boat will remain in place while we sleep, and that it will be where we left it when we return from an expedition ashore, under water, or out in the dinghy.

Aboard our 8,000-pound 31-foot Tom Wylie sailboat, Velella, we carried a 17-pound, aluminum Spade anchor. Because ours was a light, small boat, we didn’t want to carry too much weight on the bow, yet we wanted an anchor that would be secure in a wide range of conditions during a multi-year offshore voyage. It was our home, after all — small and modest as it was. We also were counting on the 240 feet of 5/16-inch chain that rested farther aft to keep us safe. My husband Garth had read about the Spade’s impressive performance for its weight in Practical Sailor, though the anchor wasn’t widely distributed at the time. In 1999, we ordered one from the manufacturer in Tunisia, hoping for the best. It arrived without incident and turned out to be a good investment.

That 17-pound Spade anchor kept our little sailboat safe over most of the 14 years we owned her. We subjected Velella and her anchor to many intense situations during our seven-year circumnavigation of the Pacific, including storms, typhoons, waves, and docks that threatened to turn our home into kindling. We never dragged anchor over muddy, coral-strewn, rocky, or sandy bottoms. Several years into the voyage, while we were in Fiji in 2003, we noticed some welding cracks on the Spade’s shank. Garth corresponded with the French manufacturer in Tunisia to get advice about re-welding the shank, so we could solve the problem in our remote location. The company immediately sent us a new anchor and it arrived quickly to Musket Cove, a resort and yachting center in Fiji. The new anchor (and the re-welded original we kept for a spare) held us throughout the rest of our 34,000-mile voyage and beyond. We certainly put the Spade to the test.

We’ve since sold our beloved Velella and are currently building a new 38-foot world cruiser designed by Garth (a naval architect) in our backyard workshop on Bainbridge Island. We hope to enjoy many more adventures aboard a larger, 14,000-pound boat. Though our new boat is not yet finished — and, no, we cannot predict exactly when it will splash — we are again considering which anchors will best suit our needs.

Happy with the Spade’s performance, over the last few years we purchased a couple more. We bought a larger Spade anchor (a 41-pound A140 for hurricane use) at a swap meet and a 26-pound A100 for kedging and to use as a spare. But we also still plan to buy another anchor or two. We consider anchors to be cheap and reliable insurance for protecting an important asset — especially one that is likely to be our future home. Because of our previous experience, we realize that an aluminum Spade may not last our entire trip, plus we know a number of people who have lost anchors in various ways during their voyages.

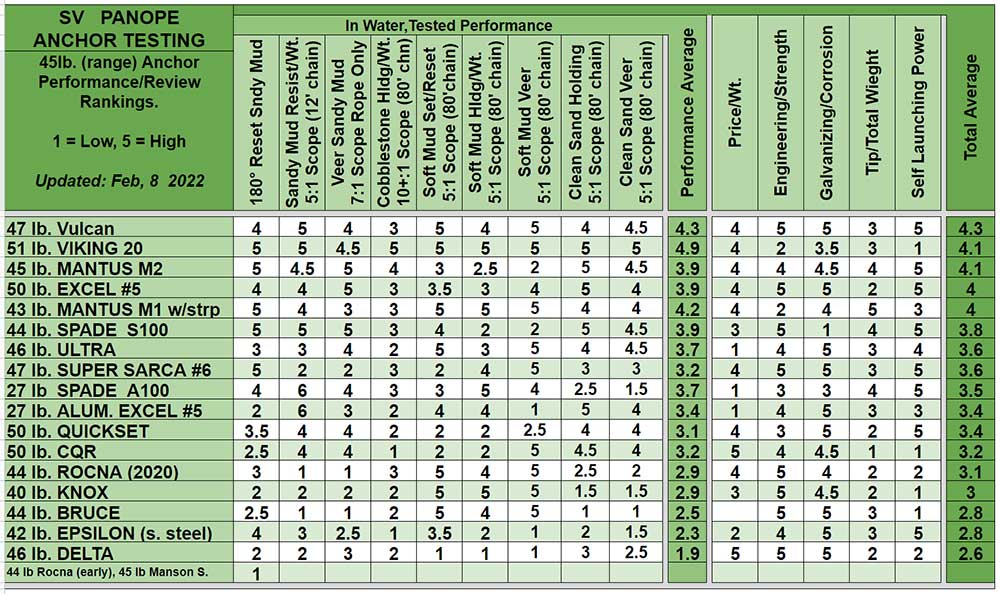

In search of data to help us make a decision, Garth hunted and pecked his way through the internet. In the course of his explorations, he came across Steve Goodwin of SV Panope, who has embarked on an impressive anchor testing regimen. Intrigued, Garth watched many of his YouTube videos and perused the data he’s produced citing the anchors he’s tested, the type of bottom, and pressure he’s subjected them to.

Like Garth, Steve has followed his curiosity in search of data. Finding insufficient information about anchors, he decided to find out for himself by undertaking a number of tests with a variety of anchors under myriad conditions. He identified an area within a decent mileage range of his home that offered varying types of bottom features and he began experimenting with dropping anchors and then trying to pull them up and get them to drag. After testing a number of them, he began sharing his discoveries online and continued searching for more anchor types to test. Over time, Panope’s YouTube channel has developed a following.

Steve was just about to test anchors in the range of one we owned and didn’t happen to have one. Since Steve lives in nearby Port Townsend, Garth thought it might be interesting to let him experiment with one of our anchors of the size he was testing. We were curious to learn how it would perform against all the others in his collection. So we stuffed the A100 aluminum Spade into our trunk and drove to Port Townsend for a prearranged visit.

We had an interesting conversation with Steve in his workshop and perused the many anchors that he is testing. We also saw his boat and the winch he uses to deploy the anchors and measure how they break from the bottom with varying types of pressure and determine whether they reset.

“What if I wreck your anchor doing the test?” Steve asked in earnest before we left our anchor in his care — or abuse, as the case might be.

“Well, wouldn’t it be better to find out if it fails before we trust our boat with it?” Garth replied with a grin.

And so, once again, we’ve put our anchor to the test — this time before our voyage begins thanks to help from a friend. And in the process, we’ve learned a lot more about the anchor options out there and their strengths and weaknesses.

Steve’s tests attempt to answer the following questions: What happens when he drops an anchor to the bottom? How well does it set? What happens when the wind shifts or current reverses? Would the anchor hold against significant pressure, would it flip around and reset, or would it just pull out?

Steve’s anchor testing system centers around a customized open powerboat with a high thrust prop and a special winch rigged to a load cell, though he’s also used his sturdy steel full-keeled sailboat Panope that his father built. He rigged a float and GoPro camera to a dozen different anchors and dropped each one on multiple types of sea floors with different scopes to record what happened. He simulates and records 180 degree swings. He’s tested in rocky bays or cobblestones, and ones with sandy mud, clean sand, and soft mud.

Steve shares his methods and the data for all the anchors he has tested, including the A100 aluminum Spade we lent him. For each anchor test video, on the screen he includes the type of seabed, depth, the length and type of chain and rode, the scope and the amount of pull pressure he’s exerting in addition to the type of anchor. You can watch and listen to his description of what occurs in each scenario, and every video is well-edited and sometimes sped up to minimize the time elapsed to witness test results.

You can see the test focused on our A100 Spade in Steve’s video #116. Overall, it performed reasonably well, although it was not the top performer in its class. Its worst performance was in cobblestones and what Steve refers to as “clean sand” (though he’s discovered during his testing that there is some binding material in the area that makes the categorization less precise). In this test case, he used 80′ of 5/16″ chain and 150′ of 5/16″ nylon rode with a scope of 5:1 in 30 feet. It dug in right away and began the first part of the veer just fine. Pulling at 500 pounds of pressure, it released. In the straight line test, the A100 Spade released at 1,020 pounds. As we make anchoring decisions, it’s useful information to know the conditions in which the A100 Spade shows its weaknesses.

While Steve’s videos may not be riveting footage for everyone, they provide valuable information for those who are interested in finding an anchor they can count on and understanding the basis for claims about its effectiveness. There’s no sales spin, just pure data from someone who aims to be thorough before drawing conclusions.

After learning so much from Steve and putting our A100 Spade to the test, what anchor have we decided to buy next? Well, we want a well-built, excellent performing anchor that fits on our bow, is fairly narrow, and isn’t another Spade. The first three criteria lead us to an Excel or a Vulcan. The Vulcan is strikingly similar to the Spade, so the Excel Steel #5 would be our first choice for diversity. But actually obtaining an Excel has proven difficult — they seem to be quite popular.

A cruiser’s choice of anchor may never be a simple one, but with information and experience, we can proceed with more confidence. Happy anchoring.

Check out Steve’s YouTube Channel and video #116 testing the A100 Spade.

Wendy Hinman

Wendy Hinman is an adventurer, speaker, and the award-winning author of two books: Tightwads on the Loose tells the story of her 34,000-mile voyage aboard a 31-foot sailboat with her husband. Sea Trials details the harrowing round-the-world voyage of a family who must overcome a shipwreck, gun boats, mines, thieves, pirates, scurvy and starvation to achieve their dream. For more information, please visit: www.wendyhinman.com