Summer 2024 is in full swing and my phone is ringing off the hook. Lately, the complaints have been far more serious in nature than usual, and they seem to be clustered in a pattern of doom and destruction—not good! The past two or three months, it seems as if the Grim Reaper has been to work on many boats around the Pacific Northwest, and my shop is beginning to fill up with new winter rebuild projects.

Summer 2024 is in full swing and my phone is ringing off the hook. Lately, the complaints have been far more serious in nature than usual, and they seem to be clustered in a pattern of doom and destruction—not good! The past two or three months, it seems as if the Grim Reaper has been to work on many boats around the Pacific Northwest, and my shop is beginning to fill up with new winter rebuild projects.

What exactly is happening, and why? Are these major issues a result of poor engineering on the manufacturer’s part, lack of maintenance or “know-how” on the customer’s part, or maybe even an earlier repair that has gone horribly wrong? How can these catastrophes be prevented?

Diagnosing major engine issues is similar to diagnosing a patient at the hospital, and when these systems onboard begin to fail, sometimes they can spiral very quickly. It’s similar to a patient going into shock with multiple organs failing simultaneously. Whether it can be prevented or not isn’t always the question, but what to do with the aftermath now becomes the focus.

MY ENGINE WAS RUNNING, DIED, AND WON’T TURN OVER

Ah, the dilemma of a marine engine plumbed with a wet exhaust. This is actually one of my most common calls, where it becomes apparent that sea water has been ingested and has hydrolocked the engine while it was being cranked, or while it was running.

How can this happen? The most common cause is cranking the engine trying to get it started and not turning off the seacock. Water cannot be compressed, so with enough of it drawn into the engine’s cylinders, the engine now will lock up and it can no longer be turned by hand or cranked with a starter.

The solution to this? Well, there isn’t always a single or simple answer, however, as soon as you know what is happening, it is critical to “pickle” the engine as soon as possible by removing injectors or glow plugs and turning the engine over to remove as much water as possible; with the seacock closed, mind you. After doing this, filling the cylinders with any sort of oil or lubricant and changing the contaminated oil and filter can make a huge difference when it comes to trying to save the engine versus replacing the unit. Many times there is minimal or no damage, so by having a client pickle their engine for me can mean the difference between scrapping the thing and simply repairing what was damaged.

MY ENGINE WAS MAKING A KNOCKING SOUND BEFORE SHUTTING DOWN

Unfortunately, this scenario isn’t the news any of us want to hear. But the truth of the matter is, your engine needs serious internal repair. Knocking, ticking, or other internal noises often are caused by lack of engine oil, excessive dirt or contamination damage, or general wear and tear from many hours of use.

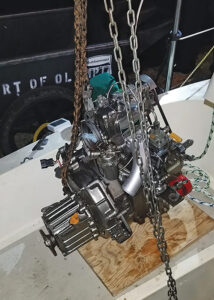

If your engine loses oil pressure for any reason such as a damaged external oil fitting, worn bearings, or catastrophic failure such as a thrown connecting rod there is almost always a guarantee that you will be pulling the engine out of the vessel to be torn down and inspected. While rebuilding an engine isn’t cheap, if done properly by a professional, it can be cheaper than a brand new engine, and is often about half the cost of a repower with a different engine. This only works if the “core” engine is in good enough shape to save, which often, it is, but is something that we need to diagnose and assess before blindly moving forward.

My assessment for rebuilding these engines includes figuring out whether the engine still is well supported, what kind of damage has been done, and whether the vessel is worth having the engine rebuilt or replaced. A marine engine overhaul is very different from a similar automotive or agricultural application. Oftentimes, it takes some effort to send parts out for machining or repair, parts may be hard to find, and finding a machine shop or other specialty shop willing to work on smaller diesels can be almost impossible in some areas. This type of work can take a lot of planning before moving forward with the project to prevent wasting a ton of money on something that can’t be saved due to lack of resources.

If you have a potential overhaul on your horizon, the first step is to have a qualified professional diagnose what happened, and what was damaged in the process so you know what you are facing.

MY ENGINE DOESN’T START EASILY OR WON’T START AT ALL

While there are many reasons why an engine won’t start easily or won’t start at all, a large cause is lack of compression. Diesels require good compression inside their cylinders in order to start easily and any fault with valves, cylinder walls, pistons, or piston rings will cause difficulty starting or inability to start. Often the minimum repair to this is a top-end rebuild of the cylinder head and valves, up to a complete overhaul with new piston rings, bearings and more.

One of the most common causes of this is poor maintenance, lack of maintenance, or poor operating habits like idling the engine excessively, not breaking it in properly or not running it hard enough to keep soot levels under control. Soot/carbon damage is very abrasive and will damage piston rings, piston crowns, cylinder walls, and valves. Most low hour engines with excessive blowby have significant soot damage and wouldn’t have had to have been rebuilt if they were operated within their recommended range under load.

All of the cases above are worst case scenarios, but they do happen and sometimes when it rains it pours. Whether it’s lack of maintenance or that the engines are just getting on in years, it seems to be pouring right now in the Pacific Northwest.

Meredith Anderson is the owner of Meredith’s Marine Services, where she operates a mobile mechanic service and teaches hands-on marine diesel classes to groups and in private classes aboard clients’ own vessels.