Exploring the quirks of the marine diesel engine cooling system.

This article was originally published in the October 2021 issue of 48° North.

It’s a beautiful sunny day, and the water is calling. Once the diesel is started for a cruise north, a weekend race, or a relaxing day sail, most of us look over the stern rail to make sure there is water coming out of our diesel’s exhaust. But that may be the last we think about our boat’s cooling system until a repair looms on the horizon.

A vessel’s marine diesel cooling system may seem somewhat familiar, but it is very unique. It is extremely efficient in what it does, as it uses the concept of convection and conduction in multiple instances to help pull away heat from various areas of the engine and reverse gear. But it can do more than just cool the engine itself. For many of us with hot water, or even cabin heaters, there usually is a coolant circuit feeding it.

A vessel’s marine diesel cooling system may seem somewhat familiar, but it is very unique. It is extremely efficient in what it does, as it uses the concept of convection and conduction in multiple instances to help pull away heat from various areas of the engine and reverse gear. But it can do more than just cool the engine itself. For many of us with hot water, or even cabin heaters, there usually is a coolant circuit feeding it.

One of the most critical, expensive, and often neglected pieces of the marine cooling system is the heat exchanger. In simple terms, a heat exchanger is a device that acts like the radiator in a car. Coolant is circulated through a reservoir with many small tubes passing through it. Saltwater (or raw water) is then pumped through these small tubes and heat is pulled out of the coolant into the saltwater via a concept known as thermal convection. The raw water then enters the exhaust stream via the exhaust elbow and is pushed overboard out of the exhaust pipe with the exhaust gas to help cool it down.

The now “cooler” coolant then re-enters the engine block to pull away even more heat. Most small diesels have at least one main heat exchanger (unless the engine itself is cooled by raw water only). For larger engines with more appliances mounted, you may find more heat exchangers that are used to cool various liquids such as engine oil, reverse gear oil, and even charge air from a turbocharger.

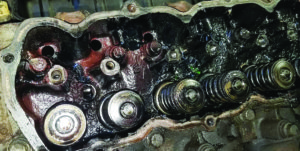

It is important to clean and inspect these heat exchangers at least once a year to make sure they aren’t leaking or clogged. Heat exchangers are typically built with metals such as copper and bronze, with various metallic fittings attached, and thus can be subject to severe galvanic corrosion if not cleaned up and watched. Most heat exchangers have a small pencil zinc(s) installed to aid in preventing galvanic corrosion, but this only helps if the zinc anode is checked and replaced early and often. In the case where an engine’s cooling system is tied to a hot water heater or cabin heater of some sort, it is important not to forget that there is a heat exchanger in that device as well. While most cores of a hot water heater or cabin heater cannot be serviced like the main engine’s, it is important to keep in mind that if there is a cooling issue, there are other outside appliances that could be a potential culprit as well.

It is important to clean and inspect these heat exchangers at least once a year to make sure they aren’t leaking or clogged. Heat exchangers are typically built with metals such as copper and bronze, with various metallic fittings attached, and thus can be subject to severe galvanic corrosion if not cleaned up and watched. Most heat exchangers have a small pencil zinc(s) installed to aid in preventing galvanic corrosion, but this only helps if the zinc anode is checked and replaced early and often. In the case where an engine’s cooling system is tied to a hot water heater or cabin heater of some sort, it is important not to forget that there is a heat exchanger in that device as well. While most cores of a hot water heater or cabin heater cannot be serviced like the main engine’s, it is important to keep in mind that if there is a cooling issue, there are other outside appliances that could be a potential culprit as well.

In the 1970s, 80s and 90s, many engine manufacturers came out with a cheaper alternative to the freshwater (coolant) cooled engines, and these are referred to as raw water cooled engines. Engines like the Volvo Penta MD6a, or the Yanmar YSM8 are examples of raw water cooled engines that had no heat exchanger and no coolant. They simply use raw water circulating through their blocks. This is a very efficient way of keeping the engine cool, as most raw water (especially in the PNW!) is very cold and there is an unlimited supply of it around the boat. These engines were designed to essentially be “disposable” as they were approximately half the cost of a new freshwater cooled engine of the same size. Their affordability made them very popular, since many folks didn’t want to spend $10k-$20k or more on a new engine. I see many of these little engines still in service 40-plus years later, if they’ve been well maintained, and have been quite impressed by them. However, cooling passages eventually become blocked if used in saltwater, or cracks eventually appear on even perfectly maintained engines. The engine itself typically has a zinc anode installed in the engine block itself to protect the iron from rotting away.

This summer has been busy with calls about overheating and lack of raw water output from the exhaust. One of the prime culprits has been seaweed or eelgrass clogging the hoses ahead of the sea strainer. The exhaust elbow is another notorious place for carbon clogging up the raw water injection passage inside the elbow itself. Running barnacle buster or equivalent cleaner through the raw water side of the cooling system and cleaning parts by hand is extremely helpful in keeping these passages clear of debris. Checking and replacing the impeller is also another good idea. Even a brand new impeller can fail from age (sitting on a shelf) and should at least be checked for cracking once in a while. Good coolant and raw water flow is required for efficient cooling. Even one blocked tube of a heat exchanger can dramatically reduce its efficacy.

This summer has been busy with calls about overheating and lack of raw water output from the exhaust. One of the prime culprits has been seaweed or eelgrass clogging the hoses ahead of the sea strainer. The exhaust elbow is another notorious place for carbon clogging up the raw water injection passage inside the elbow itself. Running barnacle buster or equivalent cleaner through the raw water side of the cooling system and cleaning parts by hand is extremely helpful in keeping these passages clear of debris. Checking and replacing the impeller is also another good idea. Even a brand new impeller can fail from age (sitting on a shelf) and should at least be checked for cracking once in a while. Good coolant and raw water flow is required for efficient cooling. Even one blocked tube of a heat exchanger can dramatically reduce its efficacy.

A freshwater cooled engine relies on coolant to pull heat away from various components, but did you know that concentrated coolant by itself has very poor cooling properties? An engine filled with 100% concentrated coolant would actually run hot or even overheat. It is actually the distilled water mixed with coolant that really helps to pull heat away from the engine. It is critical to mix coolant with at least 50% distilled water for it to function as intended. Concentrated coolant’s primary purpose is corrosion inhibition and boiling/freezing protection. It is also important to never mix different chemistries of coolants and to change the coolant when prescribed to prevent corrosion and other issues (such as gelling). Your engine’s manual is your bible. If you don’t know what coolant is in your engine, drain it and flush with distilled water prior to refilling with the proper stuff. You will thank yourself later when cooling system gaskets, and even engine parts, don’t fail!

When servicing your cooling system, don’t forget to check the less obvious components. While changing your impeller, coolant, or zinc, take the time to inspect hoses for leaks or dry rot. Painted hoses may be original and the paint can hide a lot! Water seen dripping from a weep hole in the freshwater or raw water pump body is an early sign that seals are beginning to fail and the pump needs servicing. If the system has been opened up for whatever reason or is leaking somewhere in the circuit, air in the coolant system can cause overheating until it has been bled. Exercise your thru-hull often to make sure it is functioning as intended without leaks or problems. Hose clamps corroded or even improperly installed can actually push hoses OFF the barb. Double check any professional work for quality installs, too. On numerous occasions I have found poorly done “professional” jobs.

When servicing your cooling system, don’t forget to check the less obvious components. While changing your impeller, coolant, or zinc, take the time to inspect hoses for leaks or dry rot. Painted hoses may be original and the paint can hide a lot! Water seen dripping from a weep hole in the freshwater or raw water pump body is an early sign that seals are beginning to fail and the pump needs servicing. If the system has been opened up for whatever reason or is leaking somewhere in the circuit, air in the coolant system can cause overheating until it has been bled. Exercise your thru-hull often to make sure it is functioning as intended without leaks or problems. Hose clamps corroded or even improperly installed can actually push hoses OFF the barb. Double check any professional work for quality installs, too. On numerous occasions I have found poorly done “professional” jobs.

It is the smallest of details that usually sinks the boat or causes massive failure. Take the time to thoroughly inspect all of these aspects and your cooling system will function as intended and leave you free of worries as you take to the water this fall.