When Rudolf Diesel invented and patented the design for the first pressure-ignited heat engine (commonly known as the diesel engine today), I doubt he would have expected to see the changes to performance, efficiency, and power of the same type of oil burner he came up with over 100 years ago.

Though diesel harnesses the chemical and thermal energy to move the world, it does have its drawbacks and consequences. The diesel engine has always been a fairly efficient engine — maybe not in terms of “MPGs” like we are all so used to hearing for on-highway vehicles — but more because of the fact that diesel is extremely energy dense and a cleaner burning fuel than gasoline or even some alternative lighter fuels. Diesels have exceptional thermal efficiency and much higher compression efficiency rates. In simpler terms, a smaller 2- or 3-cylinder diesel engine can do much more than its 4-cylinder gasoline counterpart without nearly the same wear and tear or effort. They can also last two or three times as long, meaning their emissions impacts are an important consideration as we try to take care of our environment.

For almost 80 years, internal combustion engines were run without any thought about emissions, efficiency, or care about the environment. That was, until the United States started drowning in the smog and soot created by these engines. In the mid 1970s, the U.S. really began to focus on cutting tailpipe emissions from vehicles, but not a lot was done for industrial or “off-highway” engines that we see in our boats. So where does the recreational diesel sit in the emissions equation?

For a majority of us, our boats were built between the 1970s and the 1990s, and when we look in our engine compartment, we do not see any sort of “emissions” equipment or electronically controlled engine components. In the early 2000s, the EPA came out with regulations assigned to certain classes of engines based on size (Hp/KW) and what they were used for. On-highway and commercial/agricultural engines are held to a higher standard as they are used for long periods of time and are typically run more frequently. These standards are divided into four “tiers” and each engine made today must meet the standards of the tier they fit in. Engines built “pre-tier” still exist, of course, but must be destroyed by engine repair shops once they are at the end of their life.

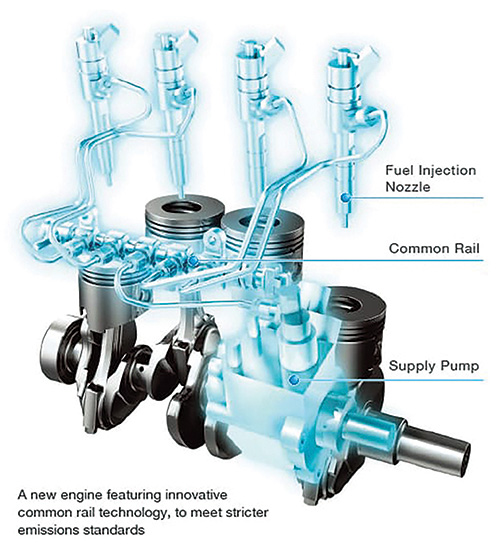

In the 1990s, we began to see electronically controlled diesels, in which an engine control module (computer) controls fuel pulse width, pressure, and timing much more efficiently than a mechanical injection pump or mechanical unit injector. This era also brought innovations to the design of basic mechanical engine components such as piston crown shapes and design, pre-combustion chambers, direct injection technology, injector spray pattern and opening pressures, and variable valve timing for the most efficient operation at all times based on an engine’s specific application.

A large change within the last 10 years has been directly controlling diesel exhaust emissions. Diesel exhaust consists of nitrous oxide (NOx) gasses, unburned hydrocarbons/fuel (HC), carbon monoxide (CO), and particulate matter/soot (PM) — which all contribute to health and environmental concerns. Exhaust aftertreatment systems are designed to capture diesel particulate and chemically convert nitrous oxides into water, CO2, and nitrogen, all of which are much safer for the environment and for us.

Many of you may have heard of Diesel Exhaust Fluid, Diesel Particulate Filters, or Selective Catalytic Reduction as these are now installed on every pickup truck, semi, and large industrial engine. If you forget to add “DEF Fluid” or try to “delete” your emissions system, your truck engine might “derate,” forcing you to pull over and fix the problem (a “derate” means that the program inside the engine computer limits either the power or vehicle speed due to less-than-ideal operating conditions). While this is good for enforcing compliance, it doesn’t work in the marine field where such restrictions could pose a safety concern in the middle of the ocean.

On recreational vessels, I am beginning to see many of the mechanical upgrades to piston and cylinder head design, electronic engine controls and monitoring, and electronic fuel systems that have become commonplace on terrestrial vehicles. Due to space limitations and cost, I have not seen much in terms of exhaust aftertreatment on the recreational front, short of mixing seawater with the hot exhaust stream to capture soot — this has not been fine-tuned yet, but I’m sure it will come. Most new recreational engines can only be held to a Tier 2-3 standard due to space restrictions and cost to implement, while larger engines are held to a Tier 4 standard (the highest tier with the greatest amount of emissions reduction parameters, including exhaust aftertreatment).

The recreational diesel world will always be 10-15 years behind the on-highway/commercial world in terms of technology advancements and implementation. However as technology improves rapidly, I see more and more small diesels following in the tracks of their large, commercial diesel counterparts; and the way of the dirty old diesel will be long gone from our waterways.

Meredith Anderson is the owner of Meredith’s Marine Services, where she operates a mobile mechanic service and teaches hands-on marine diesel classes to groups and in private classes aboard their own vessels.